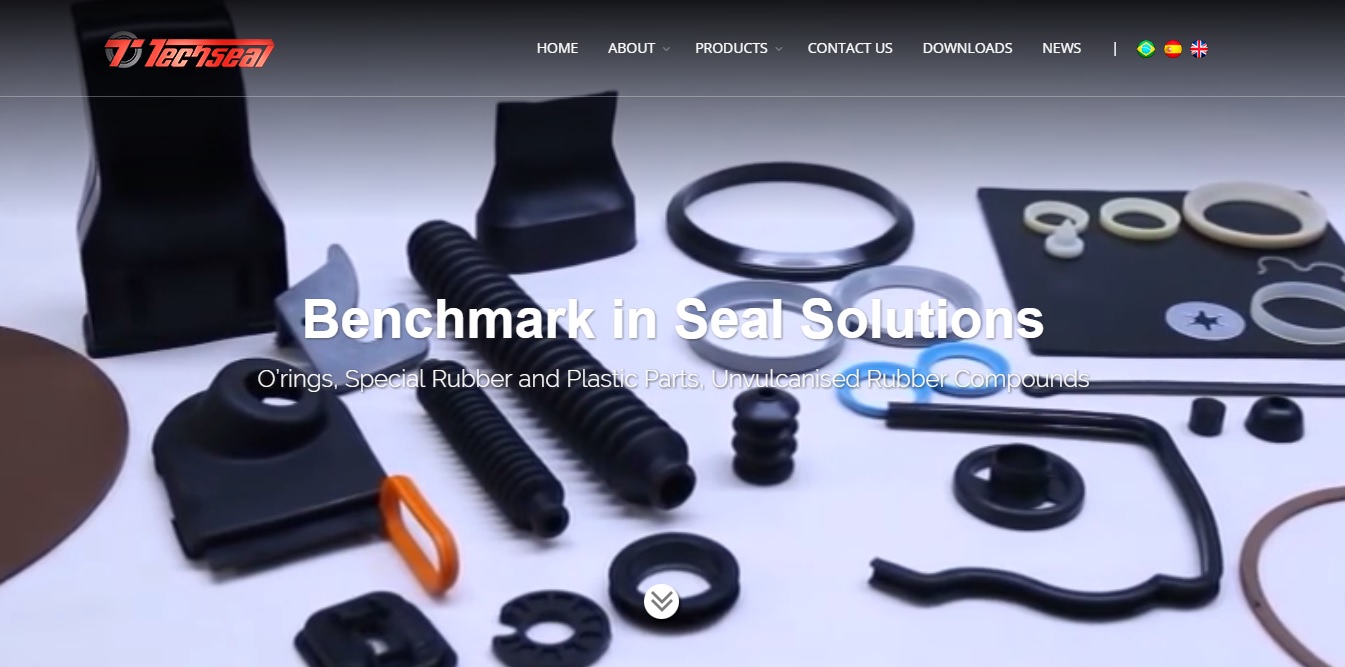

O´rings

Circular sealing parts with a circular cross section, used in static and dynamic applications. The dimension is specified by the internal diameter and by section diameter. Techseal manufactures O´rings in accordance with the international regulations such as, AS 568 among others. It´s possible to develop pieces with different dimensions from the ones on the catalogue. The compounds, which we use to manufacture thee O´rings meet very strict regulations in the market.

Rubber Compound

1- Natural Rubber (NR) / Butadiene Styrene (SBR)

The compounds formulated with SBR and Natual elastomer have excellent mechanical properties, and good resistance to abrasion, and it is recommended to manufacture sewer sealing, cushions, bushings and high strength products.

2- Ethylene Propylene Diene (EPDM)

The compounds are formulated with EPDM elastomer and they have excellent mechanical properties, high strength and high resistance to heat, light, oxygen and ozone, good resistance to low temperatures and brake fluids.

3- Acrylate Nitrile Butadiene (NBR)

The compounds formulated with NBR elastometer have excellent mechanical properties, high resistance to permanent deformation to compression, high resistance to high temperature, hydraulic fluids, mineral oils, GLP and low temperature.

4- Fluoroelastomer (FKM)

The compounds formulated with Fluoroelastomers present excellent mechanical properties, high resistance to fuel, high temperature, hydraulic fluids and solvents.

5- Polyacrylic Compounds (ACM)

The compounds formulated with ACM elastomer present excellent mechanical properties, high resistance to oils, permanent deformation to compression, high temperature, hydraulic fluids, mineral oils and low temperature.

6- Chloroprene Compound (CR)

The compounds formulated with chloroprene elastomer present great mechanical characteristics, high resistance to cooling fluids, ozone and weather, high resistance to low temperature.

7- Silicone Compound (VMQ)

The compound formulated with silicone elastomer present excellent characteristics for low conductivity products only for static application, high resistance to temperature and gases.

8- Hydrogenated Nitrile (HNBR)

The compound formulated with HNBR elastomer (Hydrogenated Nitrile) present excellent mechanic characteristics, high resistance to oils, cooling fluids, permanent deformation to compression, high temperature, hydraulic fluids, mineral oils and low temperature.

9- Fluor Silicone (FVMQ)

Excellent resistance to fuels and mineral oils, its physical and mechanical properties are similar to QMV, however it presents low resistance to hot air when compared to QMV.

Gaskets

Have as its main goal to carry out the sealing process of pneumatic systems of high and low pressure, in terms of labor temperature and environment conditions. There is always the appropriate compound to every kind of application.

Raspers

Raspers play a role of scraping and protection for pneumatic and hydraulic rods and cylinders. Its role is to inhibit particles penetration that can cause damage to the sealing elements and internal pats of the equipment. Techseal manufactures guide rollers in nylon with glass fibers or in accordance with the customer´s specifications.

Guides Seals

Are artifacts made to prevent the contact of the moving metal parts. They are manufactured with high resistance materials, Techseal develops Guide Seals compatible with different hydraulic fluids, allowing the perfect slipping of pistons and rods.

Rubber Special Parts

Are manufactured in accordance with ISO 3302 regulation, which specifies the dimensional tolerance of the product. After complying with ISO 3302 Techseal is able to manufacture Rubber Special Parts meeting our clients needs based on their designs and samples. Among others.